Posts tagged 'Shrink Wrap'

What heat tools are best to wrap my particular products?

What heat tools are best to wrap my particular products?

Are you a small business owner who needs to wrap your products?

Perhaps you make handcrafted bar soaps or candles and need an efficient way to wrap your products before shipping from your Etsy shop. Well, Mr. Shrinkwrap has you covered!

Mr. Shrinkwrap has all of the tools you will need to successfully wrap your products to keep them free of dust or debris while providing a clean and professional look.

Your primary tools will include:

- Hand Operated Impulse Sealer

- Heat Guns

- Polyolefin Shrink Film

Hand Operated Impulse Sealers

Impulse sealers are easy to operate and create a strong bond on various types of plastic or plastic-coated packaging. These sealers allow you to get as close to the product inside the packaging before sealing which creates a clean and professional look. Impulse sealers do not require any “warm-up” time making them ready to use as soon as they are turned on.

Pro Tip!

The experts at Mr. Shrinkwrap recommend selecting the 16” wide Impluse Sealer especially if it is your first one as this size can handle almost any job.

Impulse sealers range in price from $123 - $264.

If you are needing sealers for mid to high-volume production, Mr. Shrinkwrap offers other Compact Sealing Systems.

Heat Guns

While impulse sealers simply apply heat from a bar to seal a plastic bag or another plastic packaging, you may be looking for a more final product appearance. If you are wanting to tightly seal plastic around your soap or other products, you will need a heat gun.

For industrial applications, Mr. Shrinkwrap recommends propane heat guns, however, for a small business or Etsy shop, electric heat guns are typically a better option.

If you are interested in learning more about our propane heat guns, read our blogs:

The Steinel UltraHeat SV 800 Heat Gun is a dual temperature electric heat gun with a low setting of 600℉ and a high setting of 950℉. This heat gun has an industrial-grade cord and can be purchased for under $50.

If you are looking for an electric heat gun with a little more power, Mr. Shrinkwrap has you covered!

The Steinel Professional HG 2320 E Heat Gun offers an impressive range of temperatures between 120℉ to 1,200℉. The temperature is controlled by a simple toggle featuring making is very easy to use and ensures a precise application of heat onto your wrapped products. This heat gun can be purchased for under $300.

Polyolefin Shrink Film

Now that we covered the tools you will need to wrap your product, you will definitely need the actually wrapping materials as well!

Polyolefin shrink film (POF) is the perfect product when wrapping retail items.

Let’s break down what makes POF the right choice for your products:

- Premium quality shrink wrap

- Made of 100% recyclable materials

- Excellent clarity and glossy shelf appearance

- Ability to heat shrink quickly and completely

- Durable, versatile, low cost

- Excellent for bundling multiple items together

- Cross-linked POF is great for high-speed applications, providing added strength without compromising clarity and prevents build-up on sealing components

- More durable and not as affected by temperature changes

- FDA approved for food contact

- Excellent tensile-strength and propagation-to-tear

- Pre-perforated POF is available

If you want to learn even more about Polyolefin Shrink Film check out our blog post here!

Share what products you are wrapping in the comments below!

We enjoy helping you reach your goals!

If you have any questions about these products and what you need for your next project, please give us a call at 866-824-9011. We look forward to helping you meet your needs!

Service Spotlight! Contract Packaging

Did you know that Mr. Shrinkwrap can wrap your products for you?

Mr. Shrinkwrap offers Contract Packaging Services including repackaging, co-packing, and palletization. We specialize in small-batch services and have the capabilities to receive, wrap and ship all of your goods in a short turnaround time. We use our in-house sealers and heat tunnel machines in conjunction with high-quality film to pack the items you need either bundled, multi-packed, or wrapped individually.

Why use Contract Packaging?

Contract Packaging allows you to streamline your process and utilize our equipment and 20+ years of expertise. By using a contracting service you don’t have to worry about high start-up costs including equipment, materials, warehouse space, labor, and training. With our team of experts, your result will be a tight polyolefin shrink wrapped product that is suitable for a display shelf or for shipping directly to a customer as a tamper-evident and moisture resistant layer.

Benefits of Contract Packaging

- Cost Benefits

- Quality Assurance

- Expert Experience

What is Repackaging?

Repackaging is when your products are sent to our warehouse and our team of professionals wrap the products in polyolefin shrink wrap then ship them to your preferred destination.

What is Co-Packing?

Co-packing is when your products along with boxes or containers are sent to our warehouse and our team packs your products into those boxes then wraps the boxes in polyolefin shrink wrap. After your products are wrapped they can be shipped to any destination.

What is Palletization?

Once we have packaged and shrink wrapped your products we will stack them on pallets and secure those with tight stretch film. We utilize LTL Shipping Services to have your pallets delivered to any destination.

We enjoy helping you reach your goals!

If you would like to schedule or get a quote for your products to be shrink wrapped, or if you have any questions about the process, please give us a call at 866-824-9011. We look forward to helping you meet your needs!

Get started today!

Self-Adhesive Collision Wrap

What is Self-Adhesive Collision Wrap?

Collision Wrap (a.ka. windshield wrap or wreck wrap) allows the user to quickly and easily cover damaged areas with a watertight and UV resistant plastic film barrier. Self-Adhesive Collision Wrap is coated on one side with a high-tack adhesive and adheres to clean and dry surfaces such as metal, glass, or plastic, and to interior surfaces including fabric.

Collision wrap comes in four different roll widths: 18”, 24”, 36”, and 48” with lengths ranging from 100’ - 300’.

Pro Tip: While collision wrap can be used on interior surfaces it is not recommended for prolonged use. Mr. Shrinkwrap professionals advise not to leave the vehicle in direct sun or other hot environments to avoid any adhesive residue being left behind.

Who Benefits from Using Collision Wrap?

Collision wrap is primarily used by salvage companies, auto body repair businesses, dealerships, insurance agencies, and the trucking industry. By using collision wrap the value of the vehicle or other damaged equipment is preserved and is protected against further damage.

Collision wrap is especially useful when transporting a wrecked vehicle from one location to another. Depending on the type of damage, collision wrap prevents glass or other debris from falling off the vehicle and onto the road. It also helps keep loose parts from becoming dislodged and falling off during transit.

Collision wrap is also used while a vehicle or other equipment is being repaired but the damaged areas might be exposed to the elements including rain, dirt, snow, mildew, rust, or repair shop debris. While collision wrap is a temporary solution it is highly effective.

Key Features

- Tough film

- High-tack self-adhesive

- Easy application

- See-through clear plastic

- 4 MIL thickness

Collision wrap keeps damaged vehicles and equipment safe from additional deterioration. Be sure to order your supply today!

To protect the surface of nearly anything with non-see-through film, try using Multi-Purpose Surface Protection Film instead. It offers a lot of the same great qualities and temporary protection but is made for new items and can be applied to metal, plastic, glass, fiberglass, and vinyl.

Contact Us Today!

The professionals at Mr. Shrinkwrap are always here to advise you on what products will work best for you. Please call us at: 1-866-824-5881

MYTH or FACT?

Myth: Winter weather has no impact on the function of a propane tank.

Fact: Propane contracts when it's cold. When it's extremely cold outside, the volume of propane inside your aboveground propane tank will shrink, which creates a loss of pressure.

Some people underestimate the effects of cold weather on propane tanks. When temperatures drop significantly (particularly into the negatives), propane tanks will lose pressure which can result in the propane not being able to reach the gas burner rendering it ineffective.

- When the temperature of the gas reaches -44⁰ F, the propane no longer has the ability to convert into its gaseous form.

- As the propane in the tank evaporates, the remaining liquid gets colder, combined with frigid outdoor temperatures the liquid propane can soon go below the freezing point of -44 inside the tank, which makes the tank unusable until thawed.

- Cold temperatures still may also affect your propane pressure. If the pressure becomes too low, the propane inside your tank will not be able to reach your gas burner and can damage your heat tools.

- Using a nearly empty propane tank is inefficient for shrink wrapping and can damage your heat tools. Remove tanks from service at 75-80% used.

Tips to Avoid Cold Weather Issues

- Keep your propane tanks full. By maintaining a relatively full propane tank you will lessen the amount of shrinkage which will minimize the pressure loss.

- Don’t cover your tank. It may seem like a good idea to wrap your tank in a typical insulated cover to maintain a warmer temperature, however, sunlight is a much more effective option.

- If you do want to use a cover, Mr. Shrinkwrap recommends a PowerBlanket warmer.

- Clear snow and ice from your outdoor propane tank. This includes regulators, vents, piping, and valves to prevent damage that could cause a gas leak.

- Don’t pour warm water on the propane tank!

About PowerBlanket

Powerblanket products prevent fluids from freezing, protect critical materials and equipment, improve viscosity, optimize processes, keep personnel safe, and provide total temperature control and peace of mind.

PowerBlanket propane tank heaters provide a uniform barrier of heat across the entire tank. This heating solution reduces costs by optimizing temperatures and increasing propane tank efficiency.

Contact Us Today!

The professionals at Mr. Shrinkwrap are always here to advise you on what products will work best for you. Please call us at: 1-866-824-5881

Turbopack Shrink Wrap Heating Column by Ripack

Reduce manual pallet shrink wrapping times by over 60% safely and economically

The portable Turbopack Shrink Wrap Heating Column by Ripack is the ideal solution for growing pallet shrinking needs. Up to 150 pallets can be heat shrunk per day using this affordable machine.

If handheld heat shrink guns aren’t enough to cover the job but you are not ready to commit to an expensive and extensive production line, the Turbopack might be just what you need.

Key Features:

- Adjustable - heating height from 47" up to 95" (86" with optional visor)

- Mobility and speed - easily moves to the pallet and allows for quick wrapping

- Safety - 2-step ignition process

Key Benefits:

- More effective thanks to its power and its fast operation

- Economical and flexible for unparalleled value for money

How it works

The Turbopack operates on a pivoting wheel system which allows for easy movement within a working space. The adjustable visor can be extended up to 2.4m (7.87 ft) height allowing for easy shrink wrapping of a variety of pallet sizes. Once the height has been adjusted simply close the shut-off valve to secure the visor and then begin shrink wrapping. Pallets can be shrunk in as little as 60 seconds.

The trolley can hold up to 3 13kg gas bottles with each bottle able to shrink 60 pallets. This makes the Turbopack a low gas consumption (aka economical) shrink wrapping station.

Pro Tip: If you shrink long pallets or pallets of varying sizes the Turbopack is perfect because you can shrink any pallet size.

Safety

Safety is always a top priority and this Ripack Turbopack includes a two-step ignition process that ensures the machine does not get unintentionally ignited. The design also has a control handle that automatically shuts off the gas supply when released. These features provide peace of mind in knowing your equipment and operators stay safe on the job.

Let’s get technical:

- Power Developed: 190 KW

- Consumption at 100%: 26.45 lb/hr

- Operating Pressure: 2-3 bars

- Gas Type: Propane

- Weight: 242 lbs

- Max Heating Height: 95" (86" with visor)

- Passage Around the Pallet: 56 inches

Products to Accompany Your Turbopack:

- Multicover 950 - Use this machine to create your own pallet covers of varying sizes and thicknesses

- Multicover 960 E - Use this electronic machine to create your own pallet covers of varying heights while preventing waste

Check out this Ripack Official video showing just how easy it is to use the Turbopack:

Contact Us Today!

The professionals at Mr. Shrinkwrap are always here to advise you on what products will work best for you. Please call us at: 1-866-824-5881

Upgrade Your Pallet Handling Equipment

Pallet handling equipment makes moving and positioning pallets more efficient while also keeping operators safe. There are several different types of equipment for different types of jobs:

Pallet handling equipment makes moving and positioning pallets more efficient while also keeping operators safe. There are several different types of equipment for different types of jobs:

EZ Loader Pneumatic Pallet Positioner

The Bishamon EZ Loader raises a pallet to a workable height eliminating the need to bend over which in turn, increases job safety, reduces worker fatigue, and improves productivity. The self-leveling design automatically keeps the ergonomically designed EZ Loader top at the desired height.

Work smarter not harder with a Bishamon EZ Loader!

Key features:

- CAPACITY ADJUSTMENT - New Advanced Design Allows Capacity Adjustment Without Changing Air Pressure

- CAPTIVE AIR SYSTEM - Captive Air System Eliminates Cumbersome Mechanical Springs

- ENHANCED ERGONOMICS - Integral Turntable Top for Enhanced Ergonomics

Lift Pilot Floor Level Pallet Lifter

The unique space-saving design makes the Lift Pilot the smallest footprint in the industry. The Lift Pilot gives the operator full access to the sides and ends of pallets for easy pallet loading or unloading. The ergonomic design also eliminates the need for reach-over reducing the risk of back injury or chronic pain.

The innovative design of the Lift Pilot incorporates several intelligent features including telescoping forks and a patented, foot-clear, safety system. The "Foot Clear" safety design includes automatic carriage stop, pallet presence sensors, highly visible function lights, and voice commands.

Key Features:

- Floor Level Pallet & Skid Positioner

- LIFTING CAPACITY - Hydraulic Capacity = 2500 Lbs @ 24" Load Center

- FORK TYPE - Electro-Mechanically Driven Forks

- SAFETY - Post and Toe Guard Anchored to Floor

UniLift Pallet Transporter and Positioner

The UniLift Pallet Transporter allows the operator to easily lift and transport a pallet without any struggle. The durable design includes a powder-coated finish and high-quality polyurethane wheels made to last.

The UniLift is powered by an efficient 24-volt DC battery system and an on-board, automatic battery charger. It also features electro-mechanical outrigger actuation with position sensors. The operator console contains convenient buttons that raise and lower the forks and LED indicators that display the battery status.

Key Features:

- HYDRAULIC CAPACITIES – Easily Handles Standard Pallets, CHEP Pallets, and Skids to 2000 lbs. Without Straddling

- ALL-IN-ONE PALLET TRANSPORTER – Work Positioner Eliminates Need for Fork Lift and Lift Table

- APPLICATION – Ideal For Tight Work Cell Application

- ELECTRIC HYDRAULIC SYSTEM – Electric Hydraulic Powered Up and Down, Manual Push

Hand Pallet Trucks

Bishamon Blue Series Pallet Trucks are designed to easily move palletized loads with unsurpassed rollability and exceptional durability.

Key Features:

- EASY MOBILITY - Bishamon Blue Label Trucks Set The Standard For Quality, Durability, and Ease of Use

- CAPACITY - Available In 2500, 5500, and 6500 Lb. Capacities with a Variety of Fork Configurations

- PUMP OPERATION - Heavy-Duty, Rebuildable Hydraulic Pump Provides Years of Service

SkidLift

The Bishamon SkidLifts are rugged, fork-style lifts that raise loads to a convenient working height providing increased productivity and ease of mobility. The most unique feature of the SkidLift is the lower captured roller channel which provides increased stability and is safer for operators.

Manual models have an integrated foot pump while a 12-volt DC power unit provides the lifting power on electric models.

Key Features:

- LOAD CAPACITY - Load Capacities to 2200 lbs.

- EASY MOBILITY - Premium Wheels and Push Handle for Easy Mobility

- STABILITY - Unique Captured Scissor Design Provides Enhanced Stability

- MODELS - Battery Operation and Manual Lift Models Available

EZ Off Lifter

The Bishamon EZ Off Lifter pallet positioners is the ultimate ergonomic solution for loading and/or unloading pallets in applications when loads are transported with a pallet truck. The pallets are lifted to the desired height eliminating the need for excessive bending, lifting, or stretching by the operator, which increases productivity while decreasing the risk of injury.

The EZ Off Lifter has numerous safety features in place including the patented feet-clear safety circuit that automatically stops the platform 9 inches above the floor to prevent foot injuries. It is also equipped with safety warning lights and an alarm that alerts the operator before it lowers from the intermediate safety stop.

Key Features:

- CAPACITY - 1.75 in. Lowered Height with 2500 Lbs. Capacity

- ERGONOMICS - Rotating Platform for Enhanced Ergonomics

- SAFETY - Patented "Feet Clear" System for Operator Safety

- RAMP POSITIONS - 3S Model with Multiple Ramp Positions Minimizes Floor Space Requirements

All Bishamon equipment offers innovative, ergonomic designs built to increase productivity and enhance worker safety.

If you have any questions about the various pallet handling equipment and which option will work best for your needs, contact our Mr. Shrinkwrap experts at 1-866-824-372

Overwrappers

Overwrappers are most commonly seen in the food industry. The overwrappers work best when the item(s) being wrapped are placed on a tray (although it is not necessary). Overwrappers completely cover the item(s) with film and then the operator seals the bottom with the attached hot plate to prevent leakage and to keep food products fresh.

Overwrappers are most commonly seen in the food industry. The overwrappers work best when the item(s) being wrapped are placed on a tray (although it is not necessary). Overwrappers completely cover the item(s) with film and then the operator seals the bottom with the attached hot plate to prevent leakage and to keep food products fresh.

The Details:

Overwrappers come in various lengths including, 12”, 18”, 20”, 24”, 30”, and 36” rolls. Depending on the size selected will determine the overall width of the shrink wrap roll that can be used.

Overwrapper machines range in price from $300 - $1500.

Benefits of overwrapping include:

- Reduced Packaging Costs

- Extended Shelf Life of Products (protects items against dust and debris)

- Attractive and Eye-Catching Packaging

- Keeps Perishable Items Fresh

- Easy to Open Packaging

- Tamper-evident Packaging

Commonly wrapped items: food (including meats, dairy, and fresh produce), candy boxes, coffee, soup containers, pharmaceuticals, cosmetics, gift sets, and stationery.

Mr. Shrinkwrap Offers the Following Brands:

Heat Seal

Mr. Shrinkwrap is a proud distributor of Heat Seal overwrappers. Heat Seal was founded in 1950 and has been manufacturing shrink related machinery ever since. Heat Seal has always primarily been in the supermarket industry and has continued to innovate to make more efficient equipment.

Mr. Shrinkwrap offers 20 different Heat Seal tabletop and floor model overwrapping machines.

American International Electric Inc.

Mr. Shrinkwrap also offers one American International Electric (AIE) overwrap machine. AIE is a leading manufacturer, developer, and supplier of quality plastic bag and film sealing equipment. Many AIE products are manufactured in ISO-9001 certified facilities and are U/L and CE approved.

Mr. Shrinkwrap’s team of experts is always available to make sure you select the perfect item for your needs.

Call us today at 1-866-826-1996

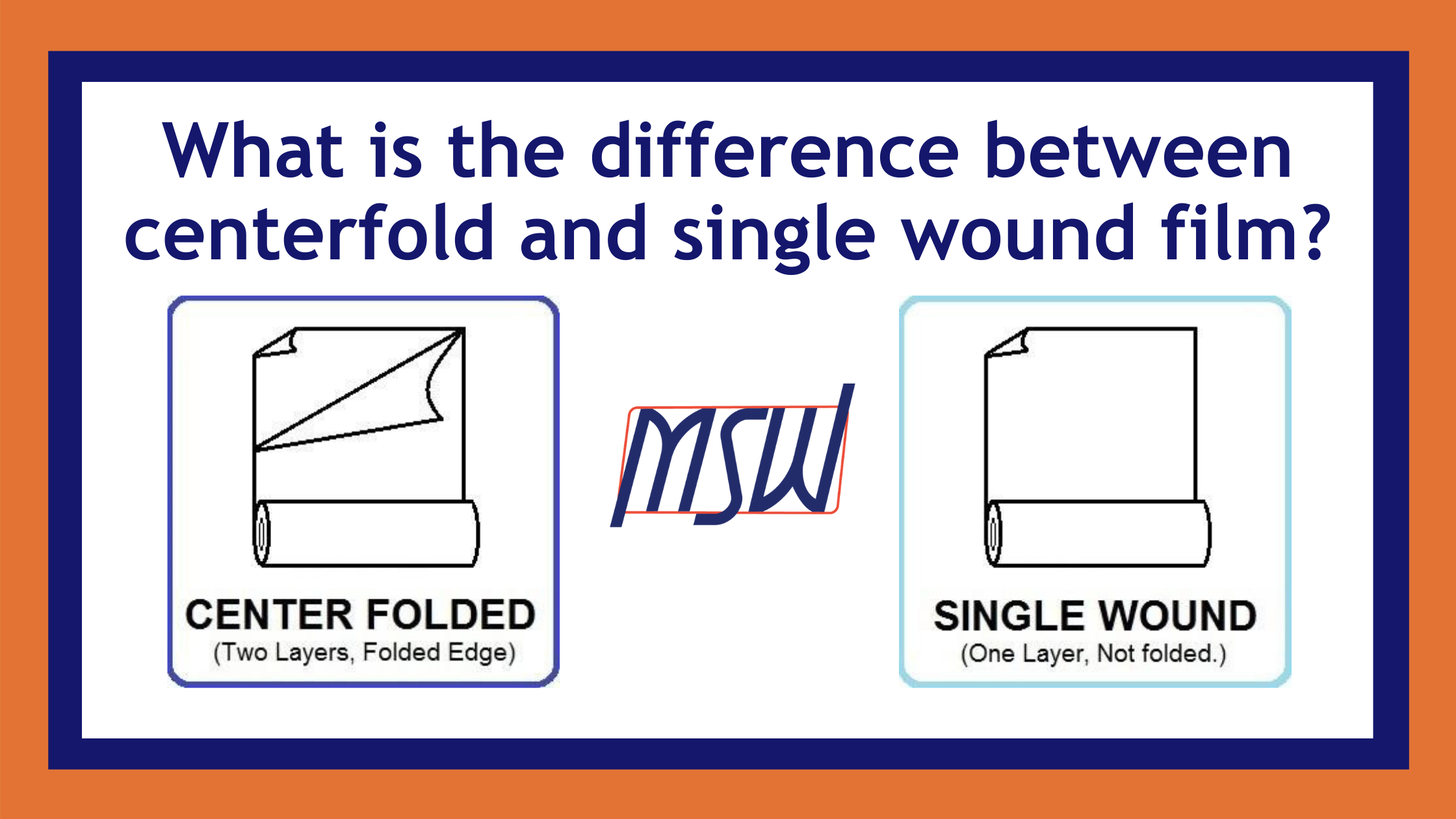

What is the difference between centerfold and single wound film?

Centerfold shrink film comes in a variety of sizes (lengths and widths) but the one key feature of centerfold film is that the film itself is folded in half lengthwise. The fold creates a sort of pocket or pouch making it easy to insert items that will be packaged and shrunk together. Centerfold shrink film is most commonly made from Polyolefin or PVC.

Centerfold shrink film comes in a variety of sizes (lengths and widths) but the one key feature of centerfold film is that the film itself is folded in half lengthwise. The fold creates a sort of pocket or pouch making it easy to insert items that will be packaged and shrunk together. Centerfold shrink film is most commonly made from Polyolefin or PVC.

It is important to note that if you have a 24” roll of centerfold shrink film, the actual width of the film is 48”.

Centerfold shrink film is used for lower output tabletop shrink machines and high-speed fully automatic machines.

Centerfold shrink film is typically used with L Bar Sealers and Bundling Machines. When using an L Bar Sealer, be sure to check the diameter of the centerfold shrink roll as many L Bar Sealers have a max diameter limit.

Single Wound Film

Single wound film is also known as lay-flat shrink wrap and comes on rolls in a single flat layer. Most single wound film is made from Polyolefin or polyethylene. Unlike centerfold shrink film, single wound shrink film is only sealed on two sides creating two holes on the ends known as “Bull’s Eyes.”

Single wound film rolls are typically used when the items being packaged are sent through a high-speed shrink machine because single wound film unwinds faster compared to centerfold shrink film rolls.

Note: Single Wound films can also be formed and sealed by hand.

Mr. Shrinkwrap has all of your shrink film needs. If you have questions please contact one of our experts

at 1-866-826-1417

Find the Right Sealer for You

Sealers are a necessary tool for many shrink wrap projects. Sealers are used to seal or weld Polyolefin film around an item. The right sealer is typically dependent on job size and familiarity with sealer equipment. Here is a rundown of the various sealers available:

Sealers are a necessary tool for many shrink wrap projects. Sealers are used to seal or weld Polyolefin film around an item. The right sealer is typically dependent on job size and familiarity with sealer equipment. Here is a rundown of the various sealers available:

Jaw Sealers

- Available in various lengths and seal bar types

- Non-stick covers on the jaws seal polyethylene, polypropylene, similar low-density films, and bubble pack envelopes

- Seals All Types of Polyethylene, Polypropylene, Cellophane, Mylar, and other High Temp Bags

- Flat or serrated jaws seal cellophane, mylar, or other high-temperature films

- Available with horizontal (chip bags) or vertical (candy bags) serrated jaws

- Jaw sealers range in price from $372 - $570

Impulse Sealers

- Available in various lengths between 8” and 20”

- Pro Tip: The pros at Mr. Shrinkwrap recommend getting a 16” impulse sealer as it covers the widest array of typical uses, especially if this is your first impulse sealer.

- Each sealer has a sealing wire that heats up when the sealing bar is closed. The sealing wire heats up the plastic film and mends it together

- Available in flat wire or round wire varieties

- Flat wire sealers do not seal and cut all in one motion. These sealers can seal the bag or film while leaving excess material for opening the sealed item

- Round wire sealers cut and seal all in one motion

- Lower heat levels allow sealing wires and tape to last longer

- Ideal for low-volume bag sealing applications

- Impulse sealers range in price from $123 - $264

L Bar Sealers

- Used to more efficiently weld the plastic film around the item being wrapped

- Compact footprint

- Uses center-folded film to create bags around products

- Many high output operations use centerfold shrink wrap film for wrapping a variety of products across multiple industries

- Semi-Automatic L-Bar standard sizes range from 15” by 15” up to 30” by 40”

- Add a Heat Shrink Tunnel or Heat Gun to an L-Bar Sealer to produce tightly shrinkwrapped packages

- Ideal for medium to high operations

- Various features depending on models include:

- sealing width

- Workspace

- ability to adjust the film dispenser

- perforated hole punch

- film discharge conveyor

- L Bars range in price from $655 - $29,990

Magic Wand Systems

- Compact sealing solution

- Ideal for creating variously sized and shaped packages

- Available in Timed Impulse and Manual Impulse options, so they can be used in manual or semi-automated production lines

- Magic wands range in price from $716 - $1,897

Bundling Machines

- Simple yet reliable bundlers

- The machine wraps products together using a film that covers the top and bottom of the package while the sides shrink closed in a shrink tunnel

- Mostly used to package cases of bottles or stacks of laundry but can also be used for single products, heavy boxes, and cases of bulk packed products

- Designed for Polyethylene or Polypropylene shrink film from a flat roll

- Bundling machines range in price from $13,000 - $26,200

Hand Irons

- Variable heat options

- Heavy-duty cast aluminum face

- Available in a variety of different widths and heating element footprints

- Non-stick covers available

- Wooden handles ensure a cool grip

- Ideal for low-volume bagging and packaging

- Hand irons range in price from $109 - $295