Centerfold shrink film comes in a variety of sizes (lengths and widths) but the one key feature of centerfold film is that the film itself is folded in half lengthwise. The fold creates a sort of pocket or pouch making it easy to insert items that will be packaged and shrunk together. Centerfold shrink film is most commonly made from Polyolefin or PVC.

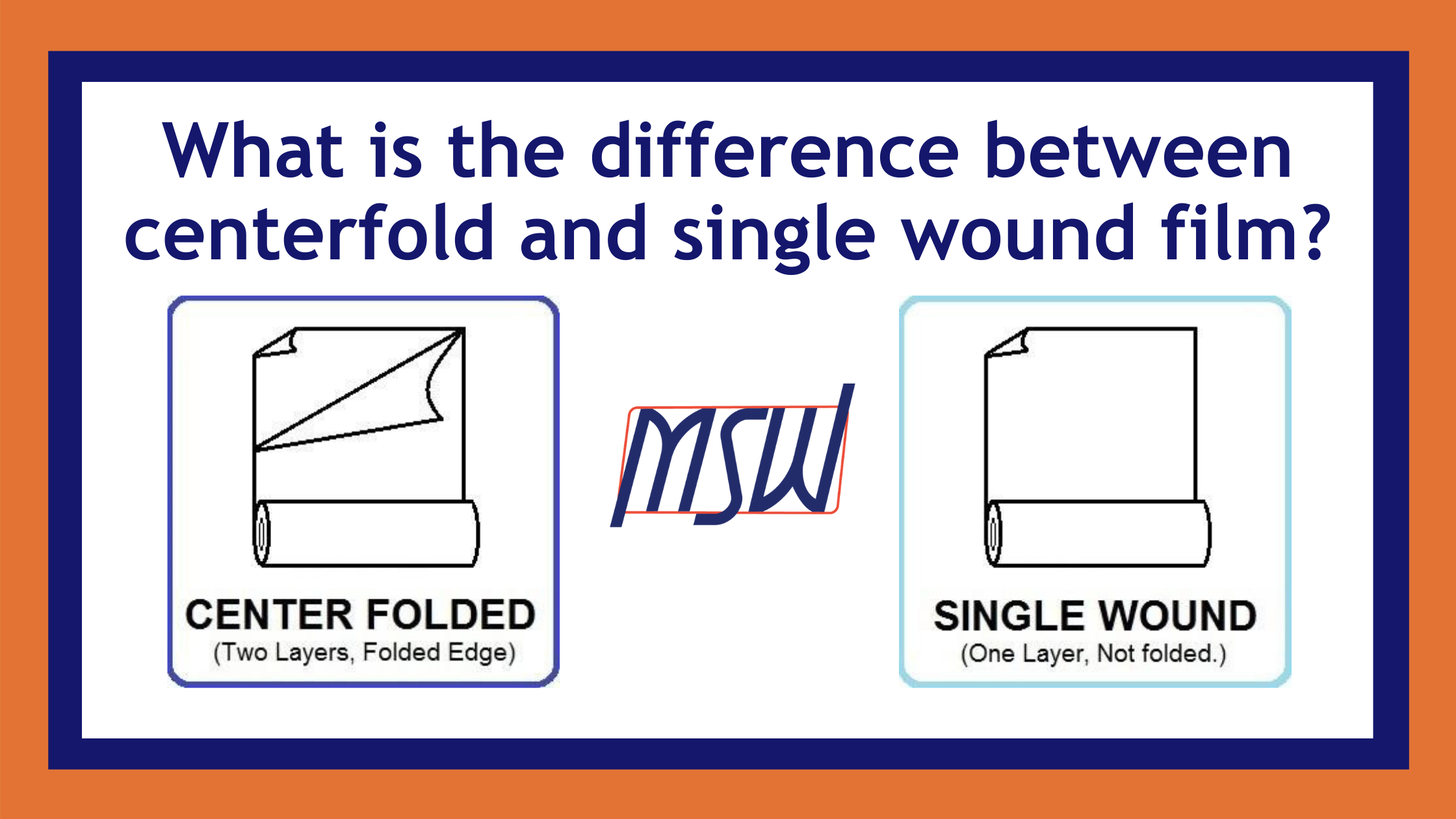

Centerfold shrink film comes in a variety of sizes (lengths and widths) but the one key feature of centerfold film is that the film itself is folded in half lengthwise. The fold creates a sort of pocket or pouch making it easy to insert items that will be packaged and shrunk together. Centerfold shrink film is most commonly made from Polyolefin or PVC.

It is important to note that if you have a 24” roll of centerfold shrink film, the actual width of the film is 48”.

Centerfold shrink film is used for lower output tabletop shrink machines and high-speed fully automatic machines.

Centerfold shrink film is typically used with L Bar Sealers and Bundling Machines. When using an L Bar Sealer, be sure to check the diameter of the centerfold shrink roll as many L Bar Sealers have a max diameter limit.

Single Wound Film

Single wound film is also known as lay-flat shrink wrap and comes on rolls in a single flat layer. Most single wound film is made from Polyolefin or polyethylene. Unlike centerfold shrink film, single wound shrink film is only sealed on two sides creating two holes on the ends known as “Bull’s Eyes.”

Single wound film rolls are typically used when the items being packaged are sent through a high-speed shrink machine because single wound film unwinds faster compared to centerfold shrink film rolls.

Note: Single Wound films can also be formed and sealed by hand.